If anyone has had the pleasure of working in a shop with heated floors, you will never want to build a garage or shop without them. It is simply the only way to have it!

Heated floors have all sorts of benefits, but in a shop it is especially awesome as it melts all your snow and is a please to stand and work on. In my case if you also use it as a man cave it makes playing darts easy, and working on a project in the winter is never a probelm. The only issue I ran into was I had to install a ceiling (bathroom) fan and run it pretty much constantly in the winter as there was a ton of condensation as the heated floors do cause the water to evaporate rapidly.

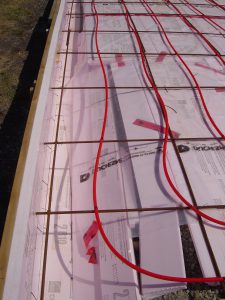

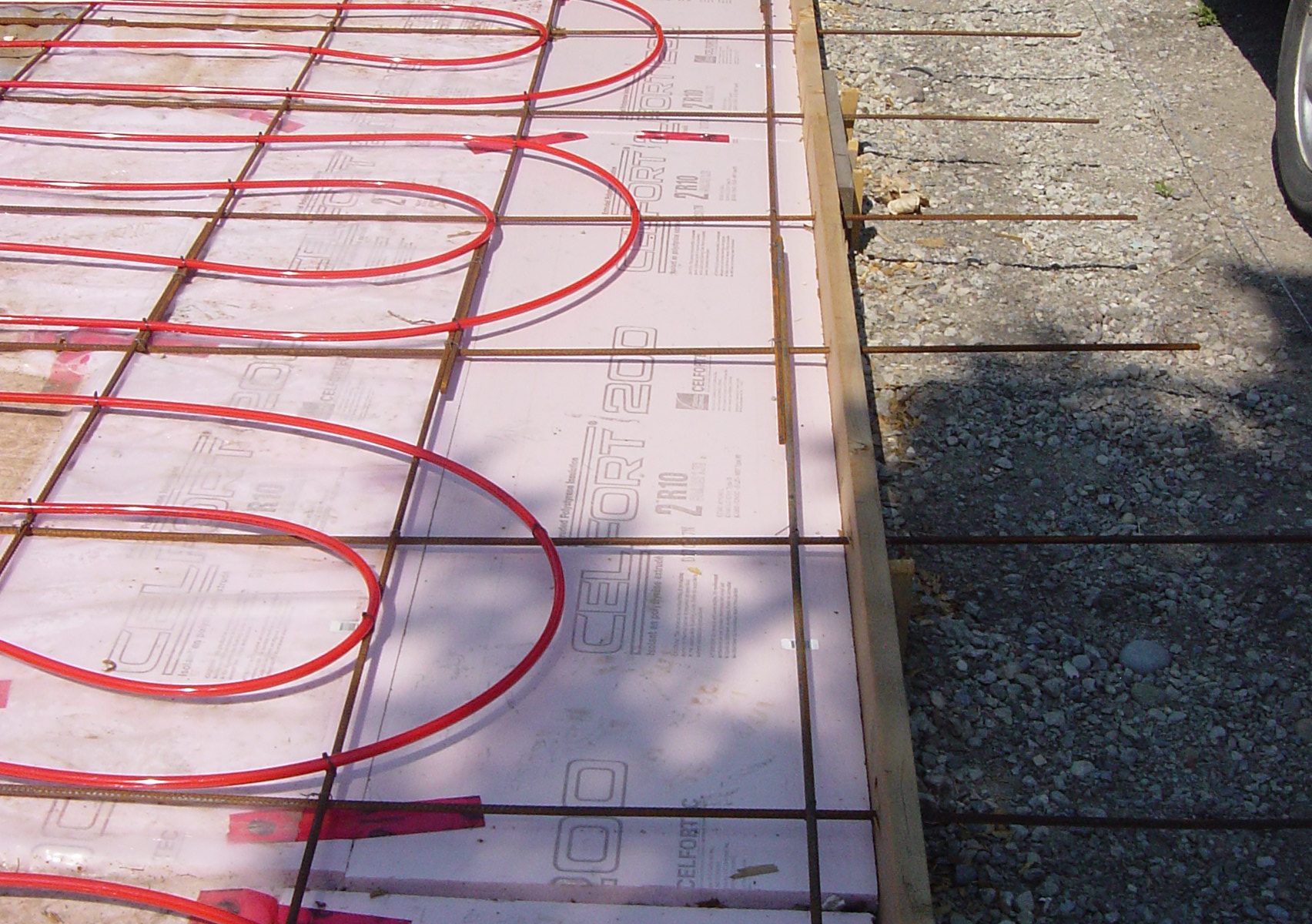

So in Canada it is cold, and in any cold climate you need to insulate the floors from the surrounding environment. This is especially important for on grade installations. So we used R20 Dow Styrofoam rated for our load overtop our plastic vapour barrier. We had to tape it together to hold it. Note it is on both the wall and floor throughout. We put a pile of nails into the walls at an angle to help hold it to the concrete when it was poured.

Once we had the vapour barrier and insulation we had to add rebar. We used a simple square grid about 1′ apart. You could use the 4″ concrete mesh but we find rebar more durable and really isn’t a ton of work. Each cross was wired together to hold it. Then we put 1/2″ floor plastic water pipe from Home Depot on top and tied them to the rebar (on top) using plastic zap straps. That held everything in place really well.

I wasn’t sure that I wanted any joins so we ran all the runs to a single point as shown in the pictures. One thing to note is we had 2 of the 3 on the double car side, so we could run that zone seperately. The single car side we ran as a single zone so we could run additional heated water flow there. We did make sure none of the pipes crossed over each other as I had heard that could cause a hole over time.

The layout patter in the pictures really worked well with even heat, so I would do it similarly again.